SINCE 2016

&

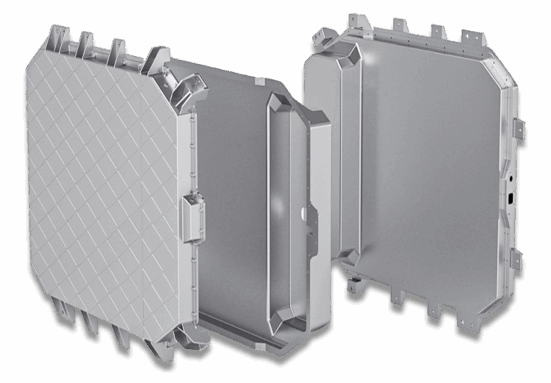

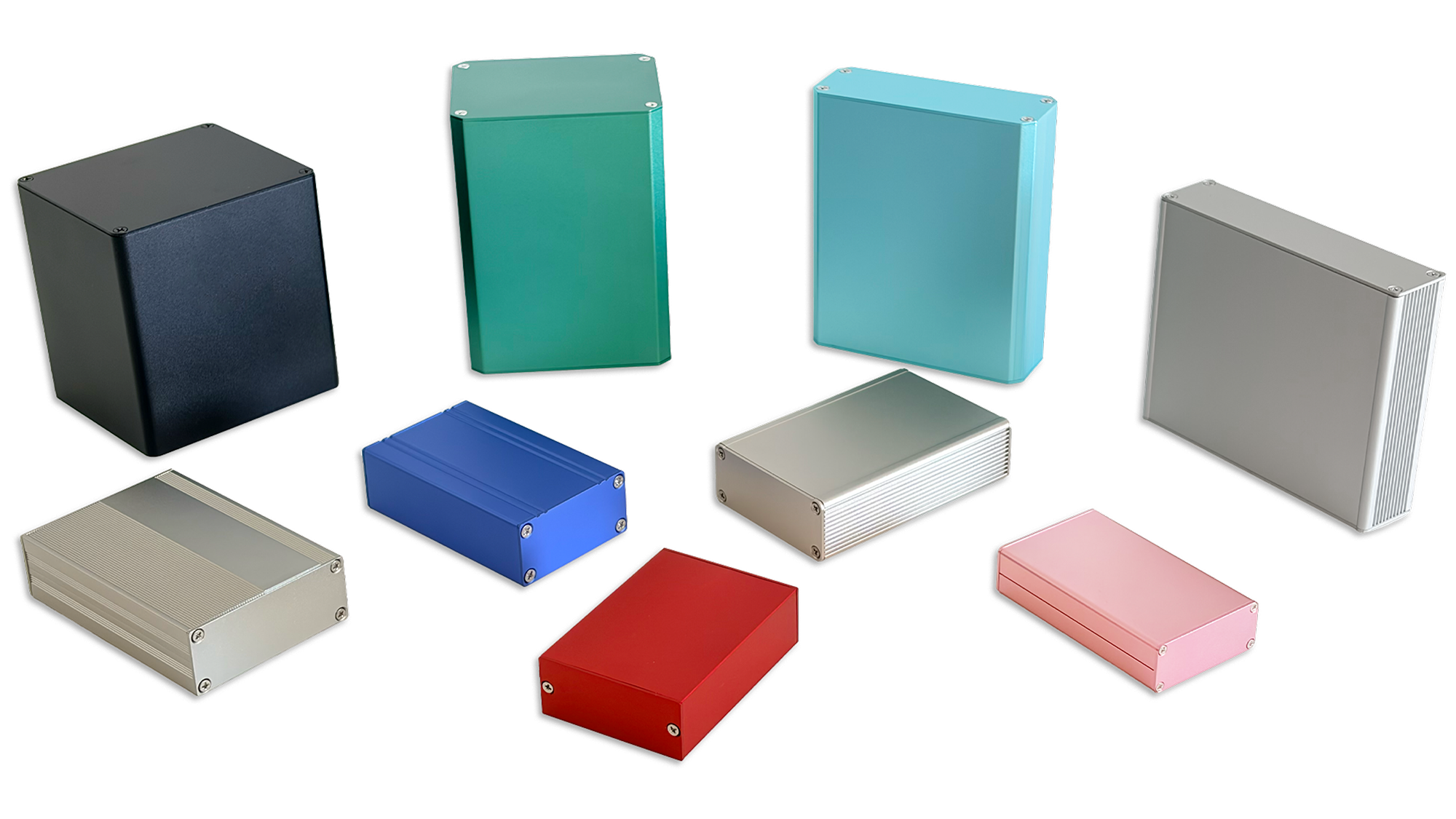

Premium Metal Enclosures

— Customized for Your Device.

High-Grade Aluminium, Stunning Aesthetics.

— Designed to Elevate Your Device.

Scalable Production, Reliable Lead Times.

-Built to Support Your Growth.

XI Mach

XISENC specializes in custom aluminum extrusion enclosures and precision metal housings for industrial, electronic, and IoT applications.

We provide a wide range of standard and custom enclosure solutions, including aluminum extrusion cases, CNC-machined housings, die-cast boxes and sheet-metal cabinets.

Customization services include CNC machining, anodizing, laser engraving, powder coating, screen printing, and modular assembly, ensuring your design fits perfectly from concept to completion.

With no MOQ and fast prototyping, XISENC helps you turn your ideas into durable, precision-engineered products.

XISENC — Shaping Metal for Your Vision.

ABOUT XISENC

Since 2016, XISENC has primarily provided metal processing and casting services in various materials, focusing on product appearance design and structural design solutions for products, ultimately delivering a one-stop production service.

12,000m² Digital Production Base

6000+ Original/Redesign Projects

20 Processing Techniques

200 Main Production Equipments

60 Customized Products for Various Scenarios

12 Inspection and Testing Procedures

XISENC SERVICE PROCESS

From model design to mass production, we ensure every step is precise and efficient.

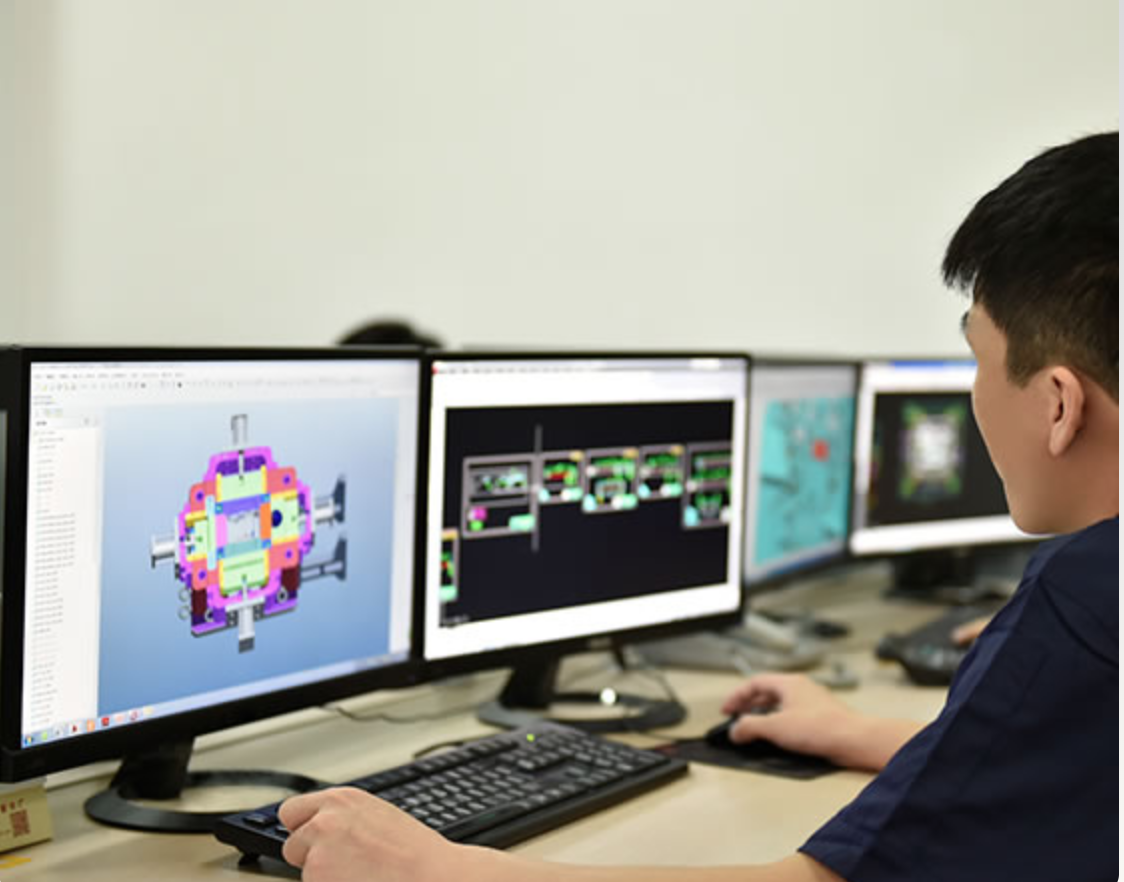

DESIGN

Precision 3D molds for Al/Zn/Mg alloys. CAD/CAE optimized for performance.

MOLD MAKING

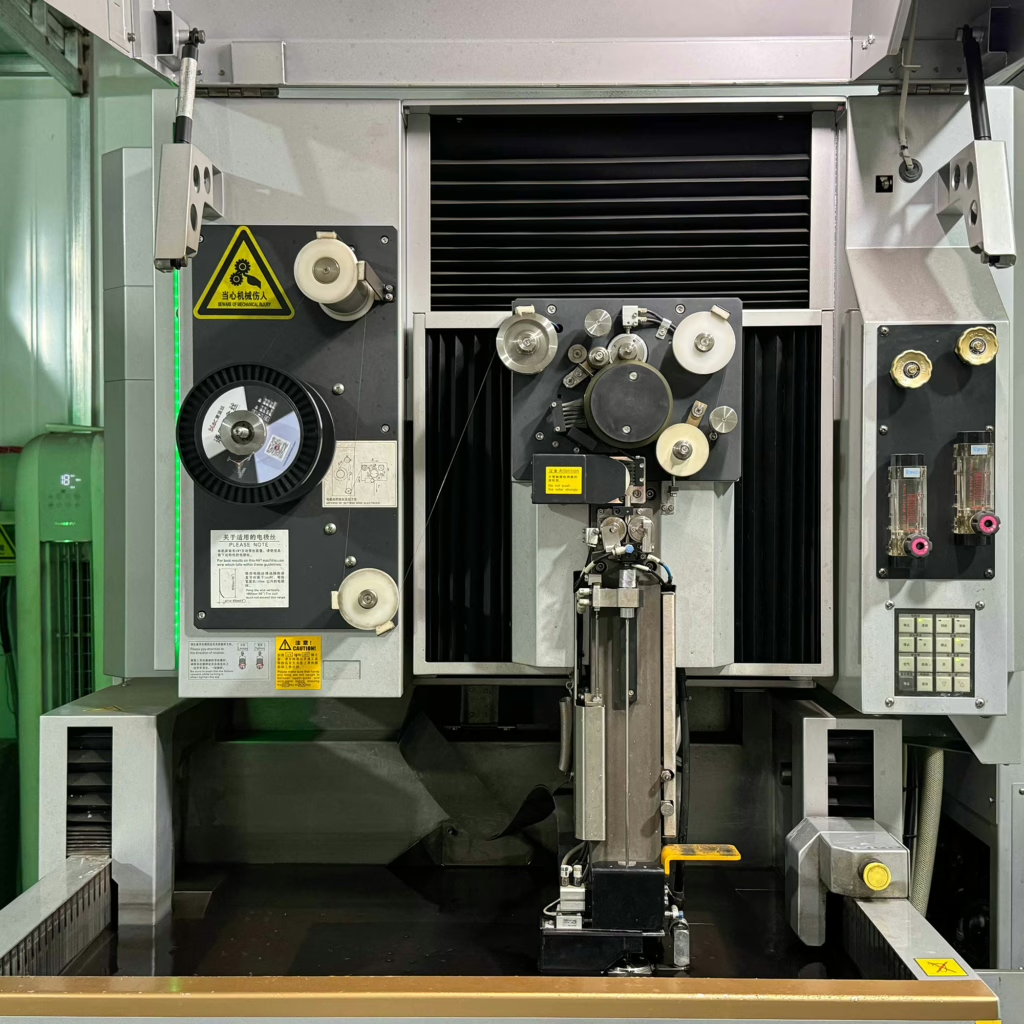

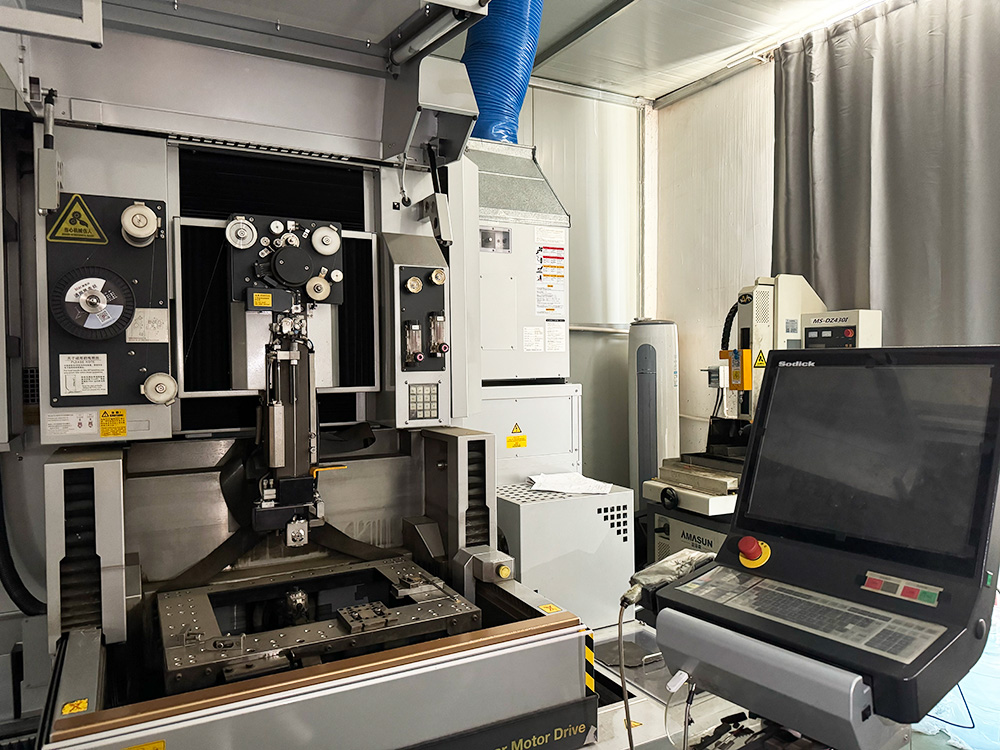

High-precision molds with strict tolerances. CNC & EDM technology for durable mass production.

SAMPLE

Fast prototypes from in-house molds. From design to testing, we ensure quality with quick turnaround.

MASS PRODUCTION

Automated production for die casting, extrusion & sheet metal. High-volume output with ±0.05mm precision & 99.8% qualification rate.

TESTING

Rigorous QC with CMM/X-ray ensures ±0.02mm accuracy & 100% compliance. ISO-certified with full traceability.

GLOBAL LOGISTICS

Global shipping via air/sea/express with tracking & customs support to 30+ countries. ISTA-certified packaging for on-time delivery.

XISENC MAIN CATEGORIES

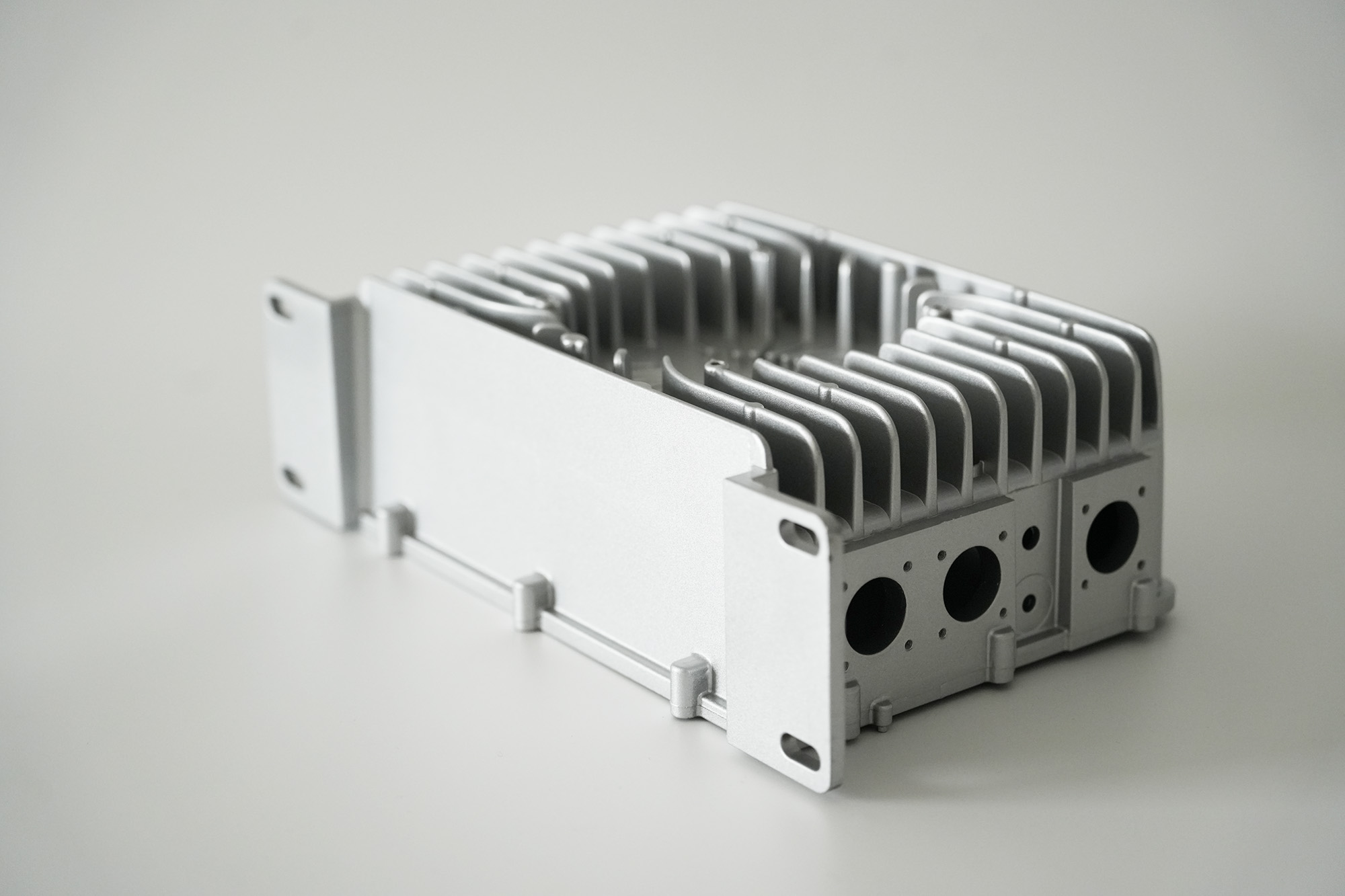

Aluminum Die Casting for High-Performance Housings

Applications: From EV battery/engine housings and 5G/AV enclosures to aerospace components and industrial IoT casings, our solutions combine durability with weight savings for critical applications across automotive, electronics, and beyond.

We utilize cutting-edge die-casting technologies—including High-Pressure (HPDC), Vacuum-Assisted, and Semi-Solid Casting—to produce precision aluminum alloy housings with superior strength, dimensional stability, and surface quality. Our optimized processes support A380, ADC12, and other alloys to meet demanding thermal, EMI shielding, and lightweight requirements.

Aluminum Profile Enclosures

We also specializes in aluminum profile extrusion, producing high-quality, precision-engineered profiles using advanced hot and cold extrusion techniques. We work with various aluminum alloys, such as 6000 and 7000 series, to achieve strength, lightweight, and corrosion resistance.

Our extruded profiles are widely used in construction (window frames, structural parts), automotive (body frames, heat exchangers), electronics (heat sinks, enclosures), and renewable energy (solar panel frames), offering durable and efficient solutions for diverse industries.

Sheet Metal Enclosures

We offer sheet metal fabrication for enclosures, combining precision engineering with high-quality materials to create robust and lightweight solutions. Leveraging advanced techniques, we achieve intricate designs, tight tolerances, and superior finishes.

These products serve a variety of industries, including electronics (device housings, control panels), telecommunications (server racks, network enclosures), automotive (battery casings, control units), and industrial equipment (protective covers, machinery housings). We focus on delivering customized, reliable, and efficient solutions to meet the unique demands of each application.

No matter what the requirements.

We’ll find the solution.

XISENC

High-pressure die casting, semi-solid die casting, aluminum extrusion, sheet metal fabrication—from XI Mach you get everything from a single source. Individually tailored to your enclosures parts production.

+86 156 2049 0719

info@xisenc.com

300400, High-Tech Zone Beichen Science and Technology Park, Beichen District, Tianjin, China