Aluminum Die Casting Housings

If you’re looking for custom aluminum alloy die-cast enclosures for automotive components, communication equipment housings, and other industrial outdoor applications—featuring precision casting, robust durability, superior heat dissipation, and high dust/water resistance—our aluminum die-cast enclosures are your optimal solution.

Aluminum Die Casting

Aluminum die-cast components are widely utilized in various sectors such as automotive, aerospace, electronics, telecommunications equipment, and household appliances, favored for their excellent thermal conductivity, corrosion resistance, and recyclability. Employing aluminum die-casting technology not only enables large-scale, efficient production but also significantly reduces material waste, making it an indispensable and efficient manufacturing solution in modern industry.

Magnesium Die Casting

Magnesium alloy products are lightweight, high-strength, and corrosion-resistant, widely used in automotive, aerospace, and electronics. They offer excellent recyclability and precision, making them ideal for applications requiring strength and weight reduction.

Zinc Die Casting

Zinc alloy products, known for their excellent casting properties, high strength, and good wear resistance, are widely used in automotive parts, electronics, hardware, and decorative items. With low melting points and superior fluidity, they are ideal for mass production, offering cost efficiency and full recyclability, making them an eco-friendly and lightweight material solution.

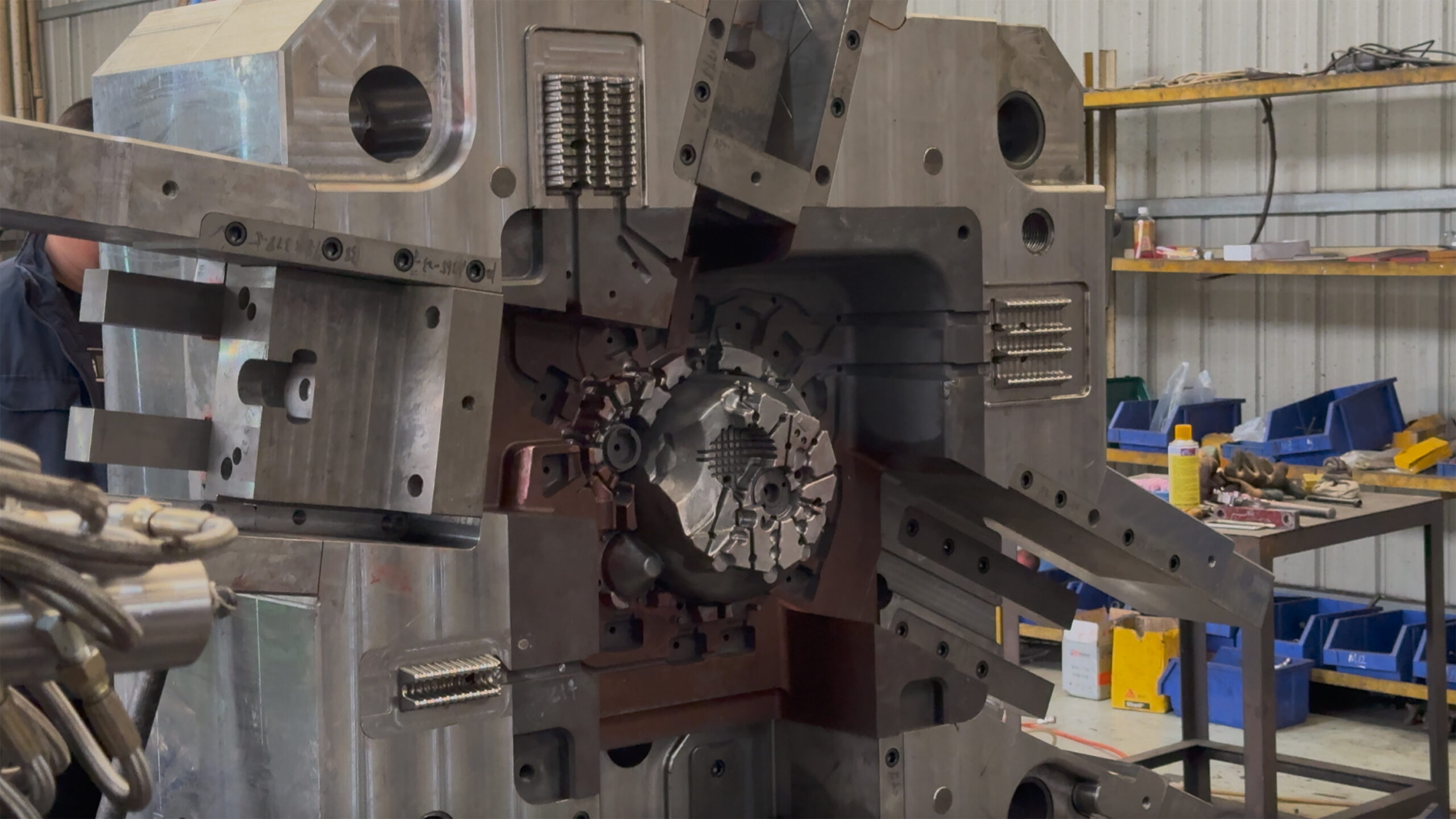

Die Casting Mold

XI Mach Mold

Professional Design, Precision and Efficiency: We utilize advanced CAD/CAE software for mold design, conduct simulation analysis, optimize mold structure, and enhance mold lifespan and casting quality.

Precision Machining, Quality Assurance: Equipped with state-of-the-art machinery such as five-axis machining centers, slow wire cutting, and mirror EDM, we ensure mold processing accuracy meets the highest standards.

Premium Materials, Long-lasting Durability: We select high-quality mold steel and apply strict heat treatment processes to ensure excellent wear resistance, thermal fatigue resistance, and dimensional stability.

Comprehensive Services, Customer-Centric: We provide a one-stop service from mold design, manufacturing, and debugging to after-sales maintenance, responding promptly to customer needs and creating maximum value for our clients.

Die Casting Solution

High-Pressure Die Casting

Die Casting

Semi-Solid Die Casting

Die Casting

High-Vacuum Die Casting

Die Casting

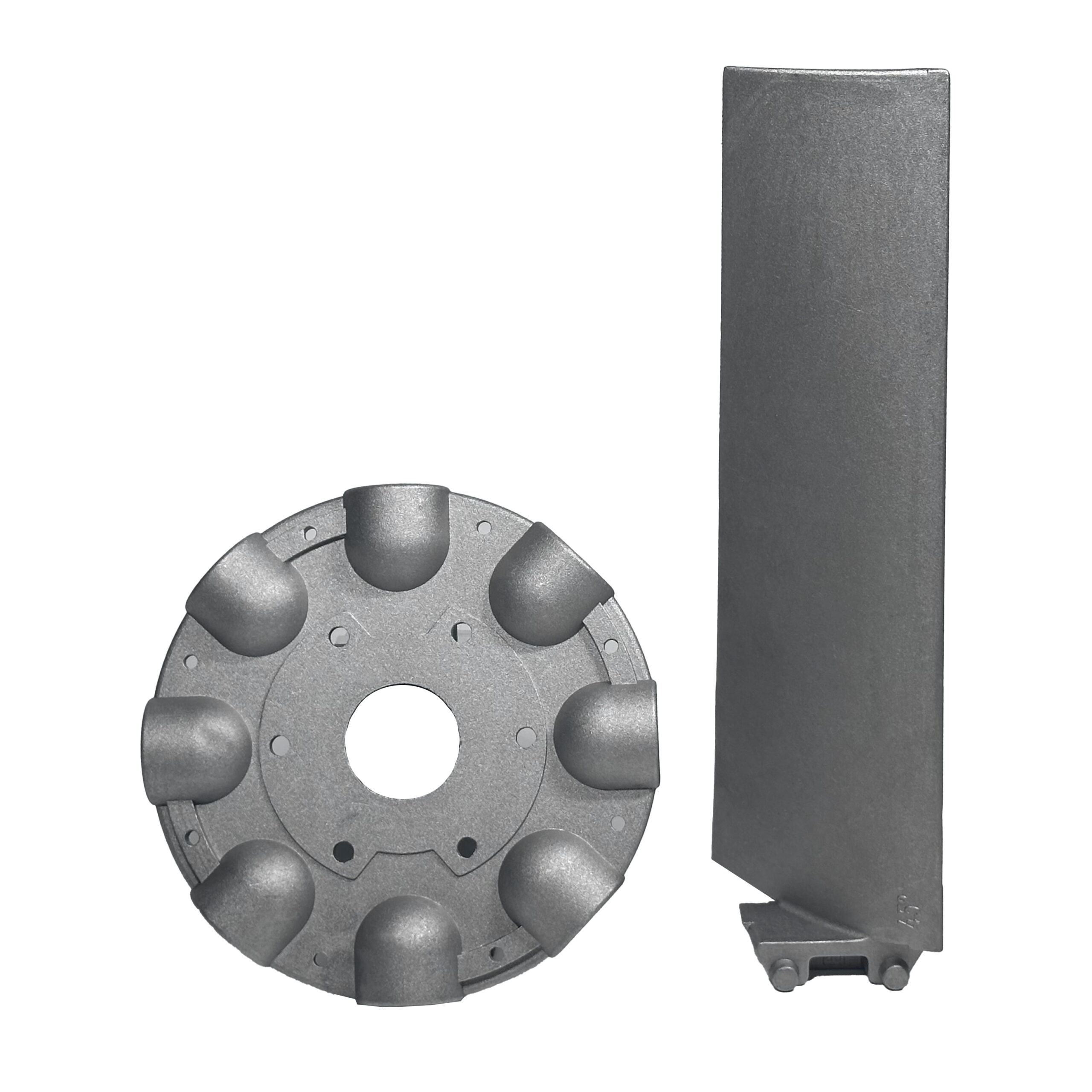

Die Casting Products

Machine Housing

Fan Blade

Gearbox Housing

Butterfly Valve

Motor Casing

Fan Clutch

Engine Part

Battery Housing

Valve Cover

Water Pump

| PARAMETER | POSSIBLE VALUES | DESCRIPTION |

|---|---|---|

| Material | Aluminum, Zinc | Different materials affect weight and strength |

| Mold Type | Single cavity, Multi-cavity, Unit die | Types of molds used in die casting |

| Casting Methods | Varies based on design | Specific dimensions of the cast product |

| Wall Thickness (mm) | 0.8 – 6.0 | Thickness of the walls in the cast part |

| Surface Finish | Smooth, Textured, Polished, Anodizing, Powder Coating, Electrophoresis, Chromate, Passivation, Shot Blasting | Type of finish applied to the casting |

| Tolerance (mm) | ±0.05, ±0.1, ±0.2 | Precision of the casting dimensions |

| Production Rate (pcs/hour) | 50, 100, 200 | Number of parts produced per hour |

| Draft Angle (°) | 0.5 – 3.0 | Angle to assist in the removal of the casting |

| Core Type | Solid, Hollow | Type of cores used in the casting process |

| Heat Treatment | Annealing, T6, T5 | Heat treatment processes for improving properties |

| Machining Allowance (mm) | 0.5 – 2.0 | Material left for post-casting machining |

| Weight (kg) | Varies based on material and design | Weight of the finished cast product |

| Corrosion Resistance | High, Medium, Low | Resistance to environmental factors |

| Application | Automotive, Aerospace, Electronics, Consumer Goods | Industries where the casting is used |

| Production Standards | ASTM B85, DIN 1688, JIS H 5302, ISO 9001 | Standards for manufacturing and measurement |

Which material or process is the perfect match?

We will be happy to advise you.

XI MACH

High-pressure die casting, gravity casting, semi-solid die casting, high-vacuum die casting, aluminum extrusion, sheet metal stamping—from XI Mach you get everything from a single source. Individually tailored to your metal parts production.

+86 156 2049 0719

marketing@ximach.com

300400, BeiChen District, Tianjin, China