CNC Machining Products

CNC Machining Parts

Precision and Excellence in Every Part

Products

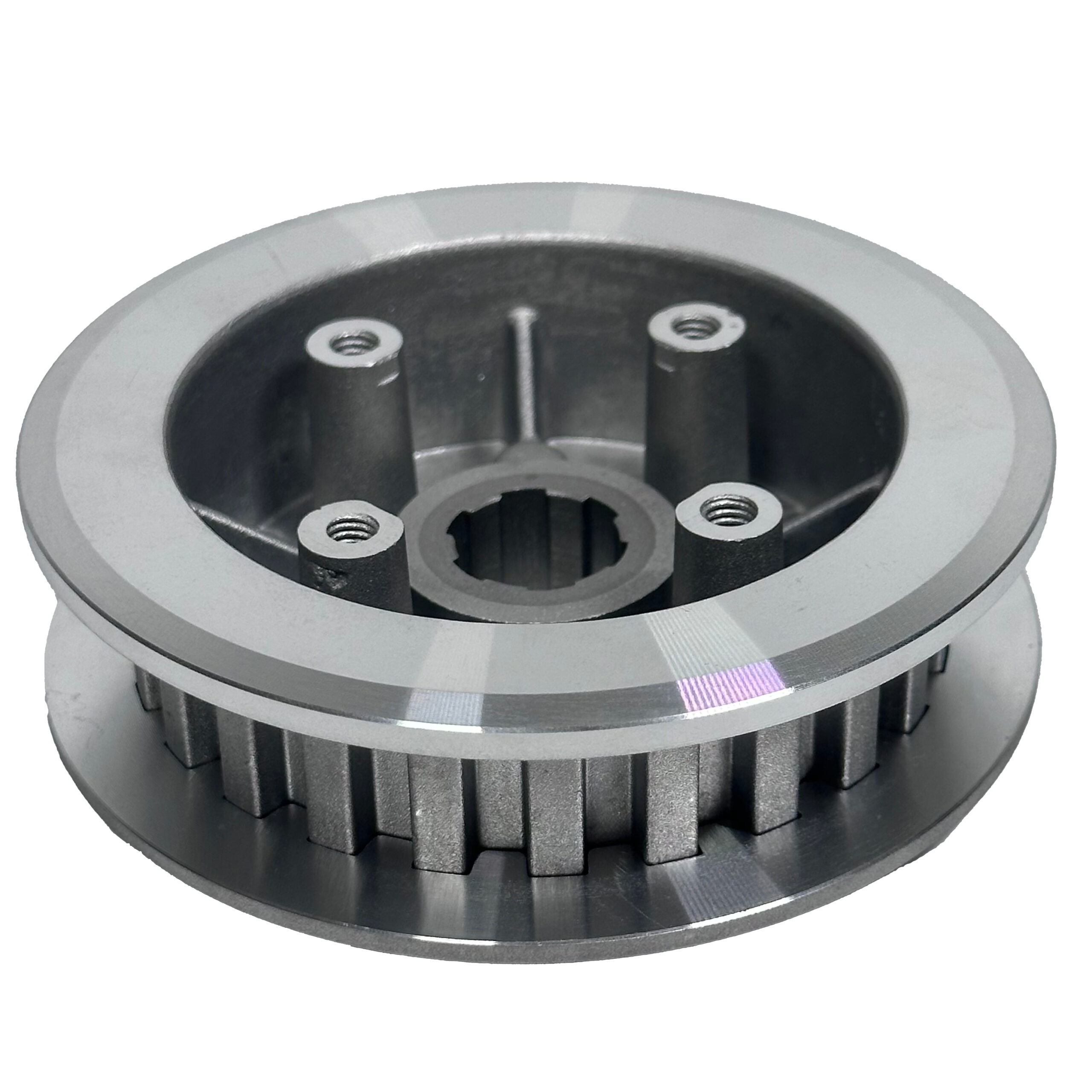

Sliding Clutch

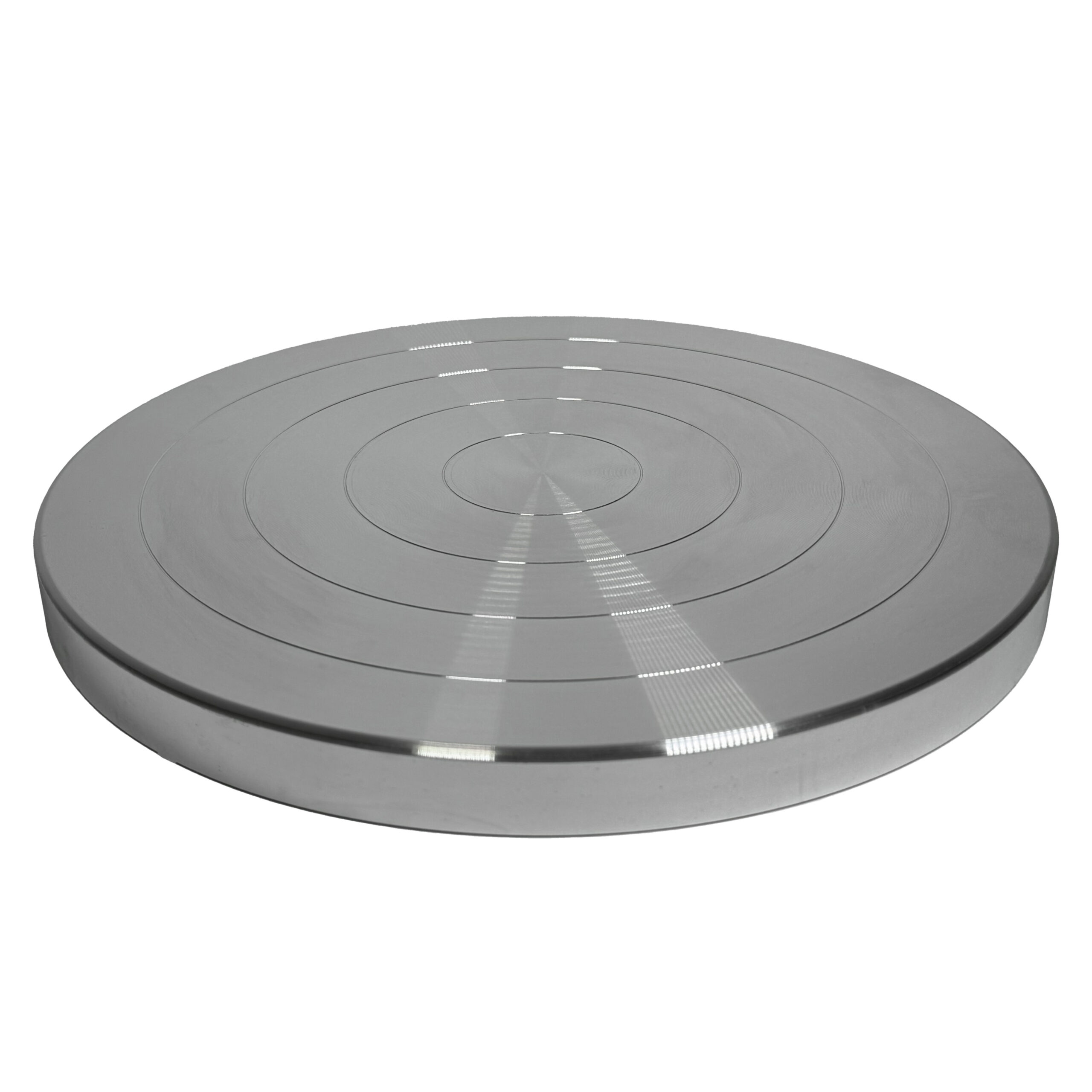

Turn Table

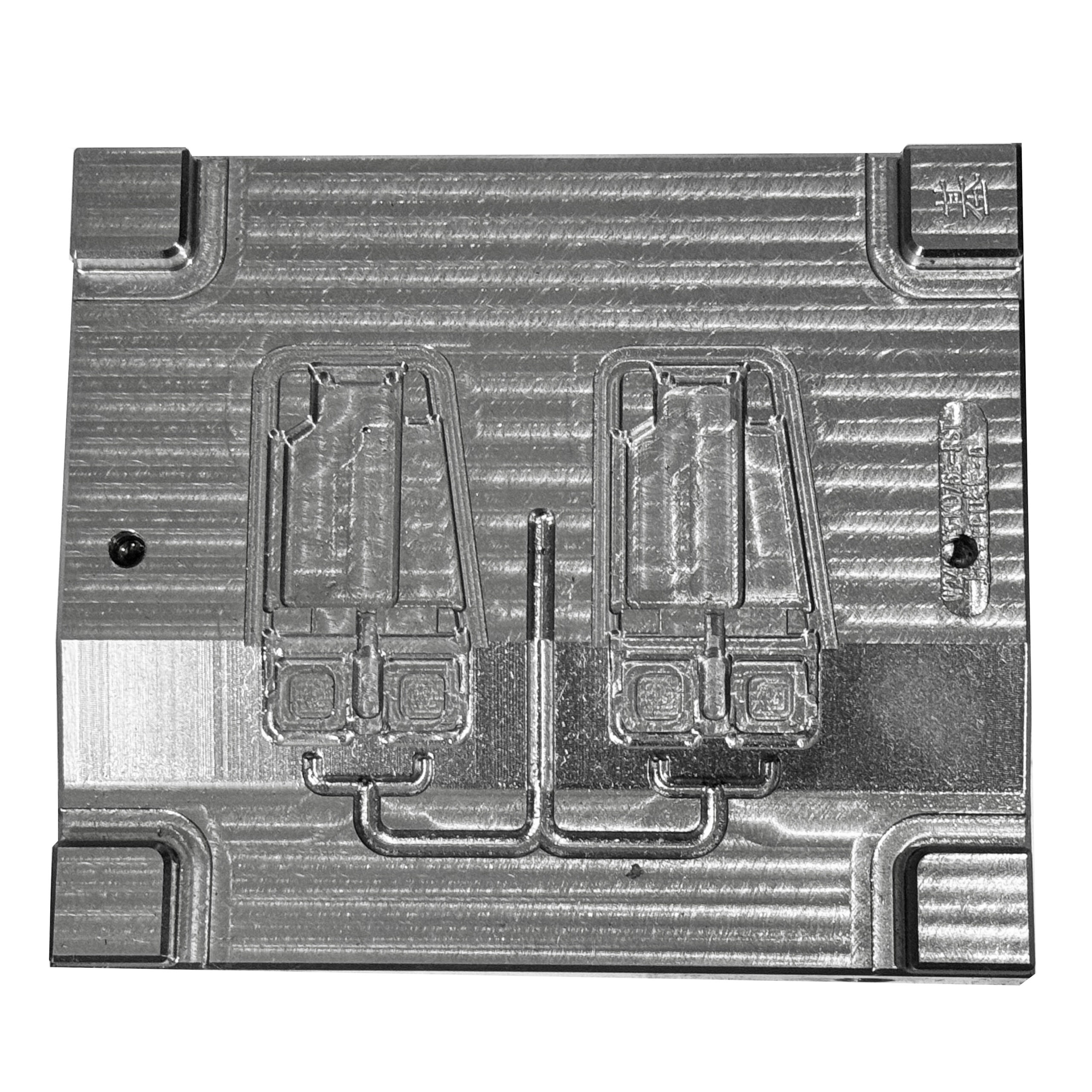

Tool Fixture

Rotary Table

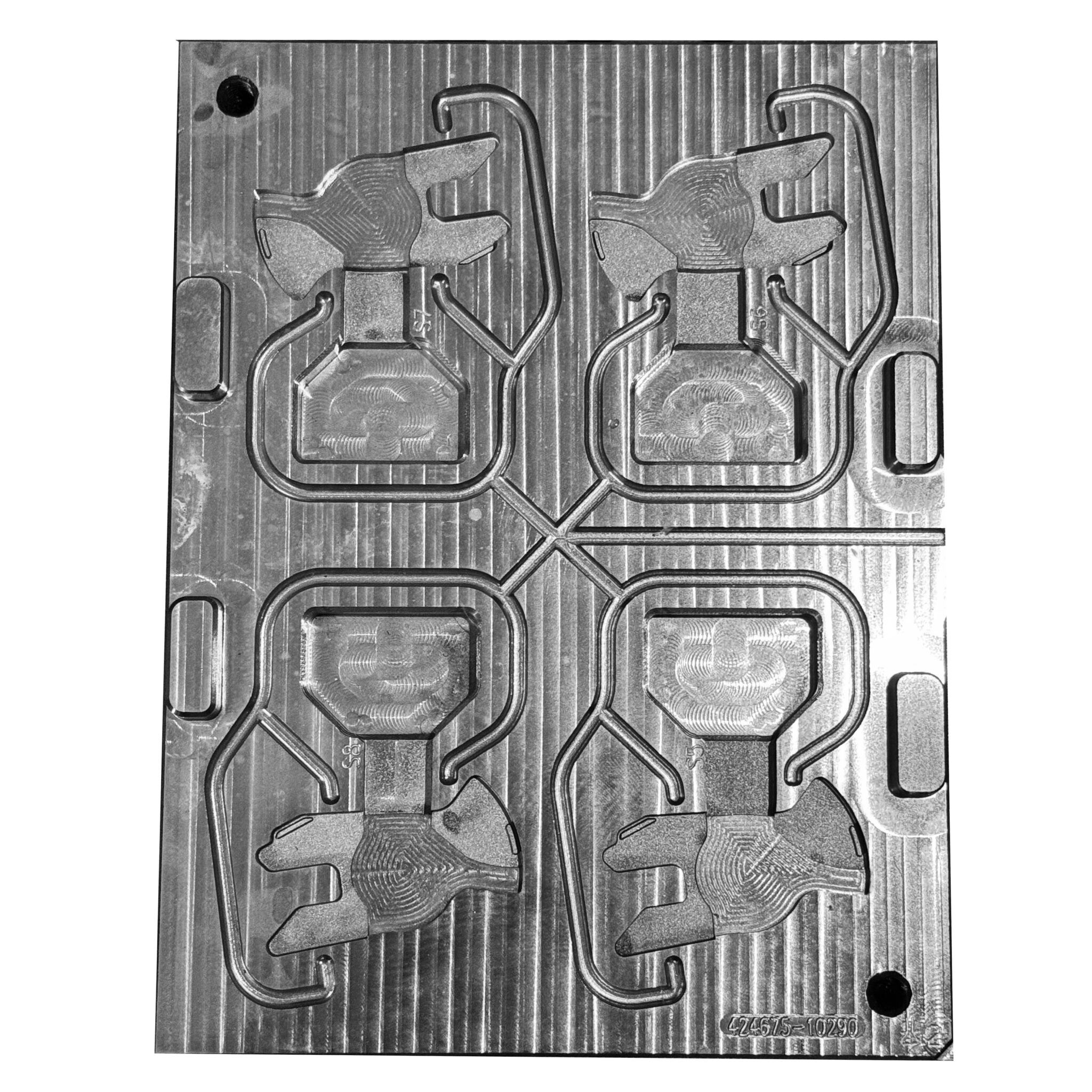

Precision Mold

Rail Hub

Fly Wheel

Precision Part

Stainless Steel Ring

Precision Mold

| PARAMETER | POSSIBLE VALUES | DESCRIPTION |

|---|---|---|

| Material | Aluminum, Stainless Steel, Carbon Steel, Brass, Titanium, Plastics | Materials used in CNC machining, affecting strength and machinability |

| Part Dimensions (mm) | Varies based on design | Specific dimensions of the machined part |

| Tolerance (mm) | ±0.01, ±0.05, ±0.1 | Precision of the machined dimensions |

| Surface Finish | As Machined, Polished, Anodized, Bead Blasting, Powder Coating | Surface treatments applied to machined parts |

| Machining Method | Milling, Turning, Drilling, Boring, Tapping | Different methods used in CNC machining |

| Production Rate (pcs/hour) | Varies based on complexity | Number of parts produced per hour |

| Tooling Type | High-Speed Steel (HSS), Carbide, Cermet, Diamond | Types of cutting tools used in CNC machining |

| Machine Type | 3-Axis, 4-Axis, 5-Axis, Swiss-Type | Types of CNC machines and their capabilities |

| Spindle Speed (RPM) | 500 – 20,000 | Rotational speed of the machine spindle |

| Feed Rate (mm/min) | 100 – 10,000 | Speed at which the tool moves through the material |

| Cutting Fluid | Water Soluble, Oil-Based, Synthetic | Types of coolants used to reduce heat and wear |

| Heat Treatment | Annealing, Hardening, Tempering | Processes to improve material properties |

| Application | Aerospace, Automotive, Medical, Electronics, Industrial | Common application fields for machined parts |

| Production Standards | ISO 9001, ISO 13485, AS9100 | Standards for manufacturing and quality control |

CNC Machining Parts

Our Advantages:

- Advanced Technology: Our 5-axis CNC machines and wire EDM equipment are equipped with the latest technology to ensure the highest level of precision and efficiency.

- Expert Team: Our team of experienced engineers and technicians is dedicated to delivering top-quality CNC machined parts that meet your specifications.

- Quality Assurance: Rigorous quality control processes at every stage of production ensure that every part meets or exceeds industry standards.

- Customization: We offer customized CNC solutions tailored to your specific needs, providing flexibility and innovation in every project.

Applications:

Our products are ideal for a variety of applications, including:

- Automotive Components: Engine parts, transmission components, and custom accessories.

- Aerospace Parts: Structural components, fittings, and custom-designed parts.

- Electronics: Housings, connectors, and precision electronic components.

- Medical Devices: Surgical instruments, implants, and diagnostic equipment.

- Industrial Machinery: Gearboxes, brackets, and custom machine parts.