High-Quality Cast Iron Components For Durability And Strength.

Gray Iron: HT200, HT250, HT300

Ductile Iron: QT400-15, QT450-10, QT500-7, QT600-3

01. Mold Design

02. Mold manufacturing

03. Raw Material Furnace

04. sand casting

05. Post-Processing

06. surface-finishing

07. quality control

Products

Heavy-duty Gear

Driven Flywheel

HandWheel

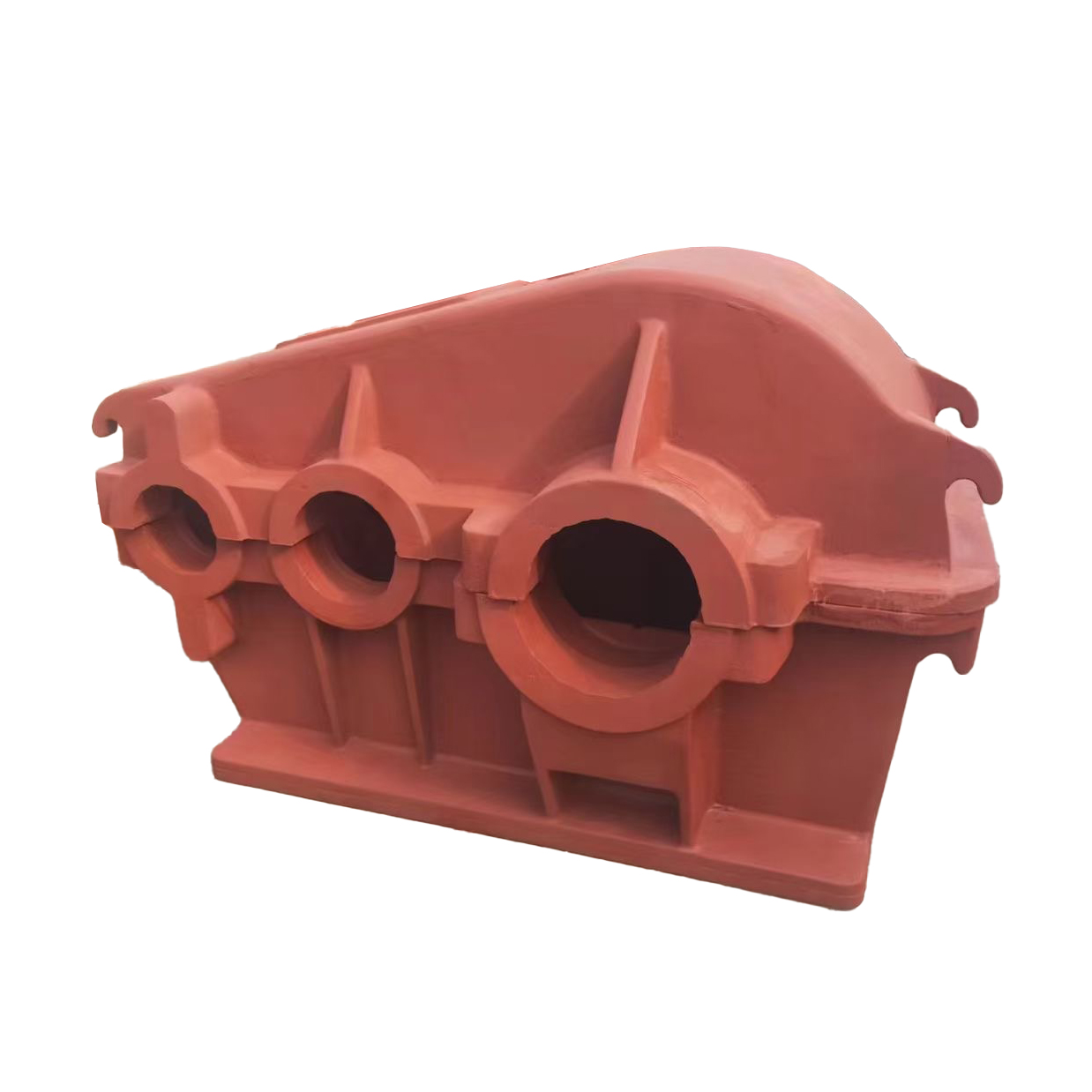

Reducer Housing

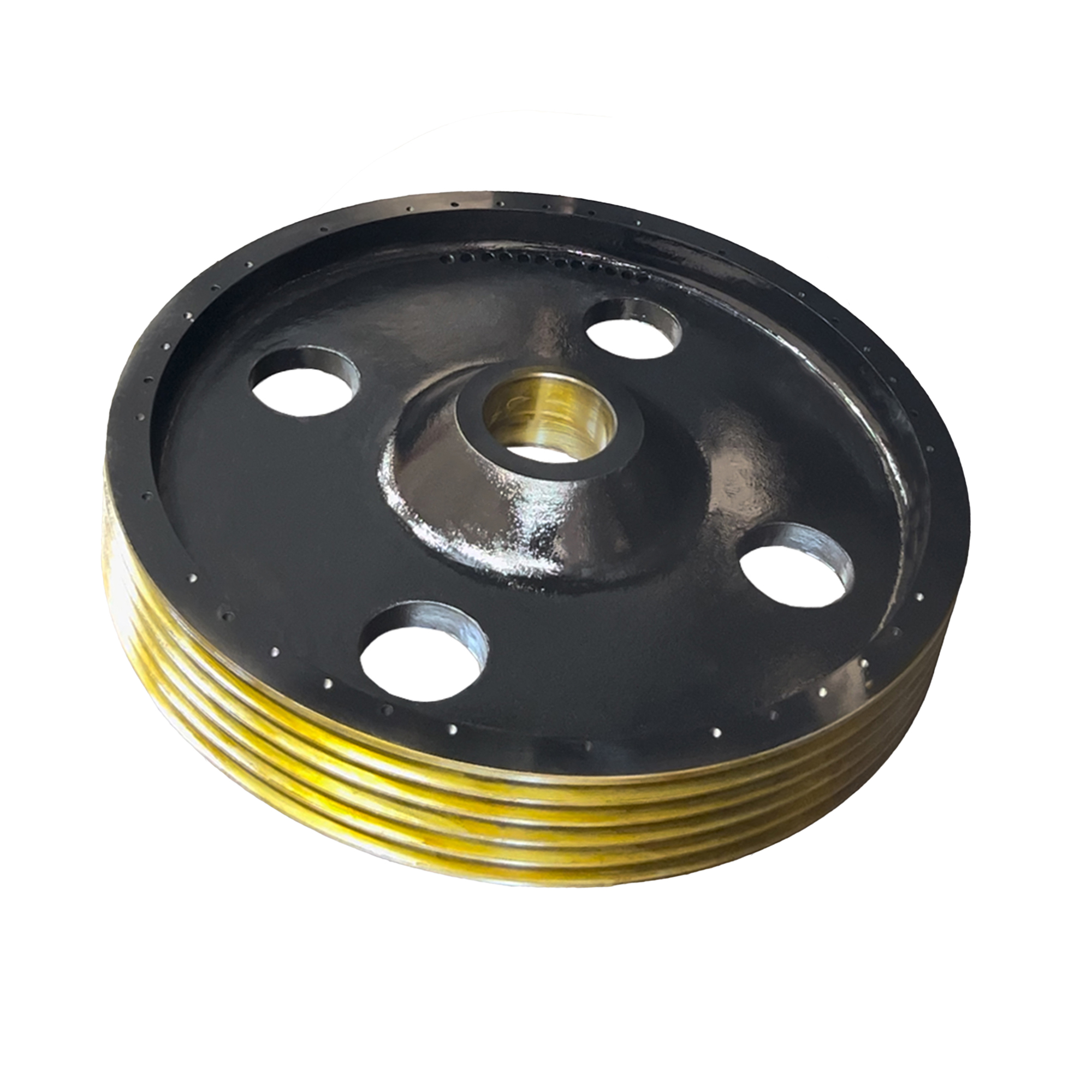

Pulley

End Cover

Shaft Body

Tee Fitting

Manhole Cover

Machinery Casing

| PARAMETER | POSSIBLE VALUES | DESCRITION |

|---|---|---|

| Material | Gray Iron, Ductile Iron | Choice of material affects the performance and application |

| Dimensions (mm) | Varies based on design | Specific dimensions of the cast product |

| Wall Thickness (mm) | 5 – 100 | Thickness of the walls in the cast part |

| Surface Finish | Smooth, Shot Blasting, Polished, Heat Treatment, Coating, Galvanizing | Methods applied to the surface |

| Tolerance (mm) | ±0.5, ±1.0, ±2.0 | Precision of the dimensions |

| Weight (kg) | 1 – 1000 | Weight of the finished cast product |

| Cast Method | Sand Cast, Shell Mold Cast, Gravity Cast, Low Pressure Cast, Vacuum Cast | Different cast methods for various applications and production scales |

| Mold Material | Sand, Metal, Graphite | Mold material affects surface quality and production cost |

| Production Rate (pcs/hour) | 1, 5, 10 | Number of parts produced per hour |

| Core Type | Sand Core, Metal Core, Ceramic Core | Cores used to form complex internal cavities |

| Heat Treatment | Annealing, Normalizing, Quenching, Tempering | Processes to improve properties |

| Machining Allowance (mm) | 2 – 5 | Material left for post-casting machining |

| Application | Automotive, Machinery, Construction, Aerospace, Energy | Common application fields |

| Production Standards | ASTM A48, ISO 8062, DIN EN 12454, ISO 9001 | Standards for manufacturing and measurement |

Our company specializes in producing high-quality cast iron products that are widely used in machinery, automotive, construction, and other industrial fields. With years of casting experience and advanced production technologies, we offer a wide range of cast iron components in various specifications and types to meet the diverse needs of our customers. Our products include, but are not limited to, cast iron machine parts, cast iron fittings, cast iron accessories, and customized castings.

We are committed to providing customized solutions based on the specific technical requirements and usage environments of our clients, designing the most suitable cast iron products for them. Whether it’s small-scale customization or large-scale production, we offer efficient and precise services to ensure timely delivery and meet the diverse needs of our customers.

XI MACH

High-pressure die casting, gravity casting, semi-solid die casting, high-vacuum die casting, aluminum extrusion, sheet metal stamping—from XI Mach you get everything from a single source. Individually tailored to your metal parts production.

+86 156 2049 0719

marketing@ximach.com

300400, BeiChen District, Tianjin, China